easYgen 3200

Presentation

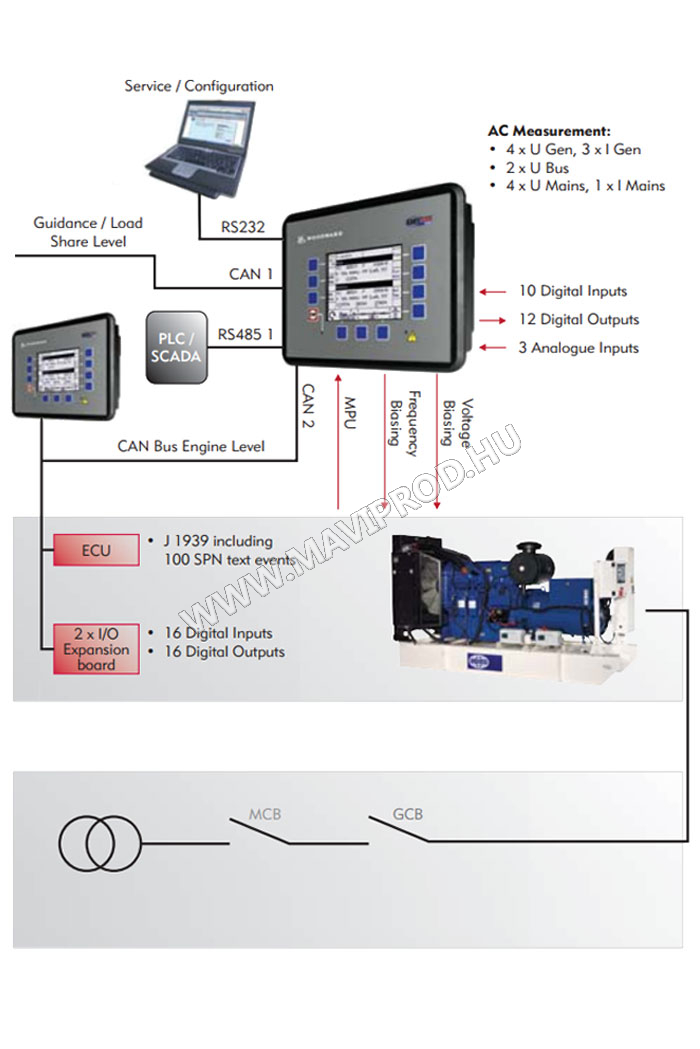

The easYgen-3200 is a versatile control unit, incorporating all the features of the easYgen-2500 including enhanced load sharing, and is adaptable to every application. Typical applications include co-generation, standby, AMF, peak shaving, import / export or distributed generation. This control panel is suitable for synchronising up to 32 generator sets running in island mode, mains parallel and multiple unit mains parallel operations.Benefits

- Capable of generator set-to-set, set-to-mains and multiple set-to-mains synchronisation for up to 32 generator sets

- Enhanced system flexibility meets demanding customer specifications

- User friendly interface via 320×240 pixel graphical interactive 5.7” LCD

- Easy system navigation via programmable soft keys

- Multilingual capability: English, Chinese, French, German, Italian, Japanese, Polish, Portuguese, Russian, Spanish, Turkish and Finnish

- Multiple communication protocols for communication with Engine Control Units (ECUs), external I/O boards, PLCs and modems

Features

- Power and reactive power load sharing up to 32 units including load-dependent start / stop

- Engine start / stop and generator set measuring and protection

- Automatic base loading

- Running hours balancing

- Import / export control

- Dead bus closure negotiation

- ECU monitoring and alarm management as well as remote start / stop and control commands

- PLC-like programming with Logics Manager

- 300-entry, time and date stamp log

- Operating hours / start / maintenance counters

- Configurable trip levels / delays / alarm classes

- Field configurable application settings

- Multi-level password protection

- RP3000 remote display panel available for management and control from adjacent plant room

Protection

Generator Set- Over / under voltage and frequency

- Dead bus detection

- Overload

- Unbalanced load

- Reverse / reduced power

- Time over current

- Instantaneous over current

- Measured ground fault

- Phase rotation

- Power factor

- Over / under speed

- Battery over / under voltage

- Auxiliary excitation

- Speed / frequency mismatch

- Over / under voltage and frequency

- Phase shift

- Rotation field

Inputs / Outputs (I/O)

- Two separate sets of 3-phase true r.m.s. voltage measuring inputs for the generator set and mains, and 2-phase busbar voltage

- 3-phase true r.m.s. generator set current / power

- 1-phase true r.m.s. current input freely configurable

- 1 speed input (magnetic / switching)

- 10 configurable discrete alarm inputs

- Up to 12 programmable discrete outputs

- Three configurable analogue inputs

- Two configurable analogue outputs

- Two CAN bus communication networks (up to 32 participants, isolated)

- Two serial ports supporting Modbus RTU Protocol, RS-485 and RS-232 (isolated)

Optional features

NetBiter FGW200

Remote management for new and existing generator set installations.With software designed exclusively for FG Wilson, the FGW200 offers new opportunities for remote access over the internet and mobile phone. The NetBiter unit is suitable for use in new and existing installations due to control panel Auto Detect software which offers plug and play capability.

Remote management at a new level

- Reducing the need to travel to remote sites for maintenance purposes

- Minimising downtime with instant information about equipment health

- Theft prevention through generator set tracking

- Fuel level monitoring to optimise fuel inventory

- Start up logging to help prevent generator set misuse

- Allowing multiple project and device management through NetBiter.net

Features

- New Auto Detect software allows retrofit to PowerWizard 2.1, easYgen-2500, easYgen-3200 control panels and ATI transfer panels

- Built in web interface for data monitoring

- Built in alarm manager for SMS, email and SNMP

- Built in data logger of historical trends

- GSM / GPRS modem included

- All software included, easily upgraded remotely and provided with no licensing cost

I/O Expansion Module†

Connection to and from external system devices enabling more flexibility to meet your specfic power requirements.Features

- 8 configurable discrete alarm inputs

- 8 configurable relay outputs

- Connection to easYgen control panel via CAN bus

- Input and output configuration via onboard easYgen relay manager

- Remote control of output relays via CAN bus

- The I/O Expansion Module can be used with other manufacturer’s controls. Consult Woodward product manual 37135 for information regarding the address assignments of the CAN bus interface

– Aviable through Power Solutions†

| FG100 | DSE4520 | DSE7320 | DSE7410 | DSE7420 | PW1.1 | PW 1.1+ | PW 2.1 | PW2.1+ | MRS16 | IG200 | EG2500 | |

| Control Function | Auto Start | Auto Mains Failure | Auto Mains Failure | Auto Start | Auto Mains Failure | Auto Start | Auto Start | Auto Start | Auto Start | Auto Start | Sync | Sync |

| I/O | ||||||||||||

| Digital Inputs | 6 | 4 | 8 | 8 | 8 | 4 | 6 | 6 | 6 | 7 | 8 | 10 |

| Dedicated E’stop Input | x | x | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | x | ✓ | x |

| Digital Outputs | 5 | 4* | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 6 | 8 | 11 |

| Dedicated Fuel And Crank O/Ps |

x | ✓ | ✓ | ✓ | ✓ | x | x | x | x | x | x | x |

| Analog Input | 3 | 3 | 6 | 6 | 6 | 2 | 3 | 3 | 3 | 4 | 4 | 4 |

| Mpu Input | x | x | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓** | ✓ | ✓ |

| Rs232 | x | x | ✓ | ✓ | ✓ | x | x | x | x | Option | Option | x |

| Rs485 Modbus | Option | x | ✓ | ✓ | ✓ | x | x | ✓ | ✓ | Option | ✓ | ✓ |

| Can Bus Engine | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 2Nd Can Bus | x | x | x | ✓ | ✓ | x | x | ✓ | ✓ | x | ✓ | ✓ |

| USB | ✓ | ✓ | ✓ | ✓ | ✓ | x | x | x | x | ✓ | ✓ | x |

| Ethernet | x | x | x | ✓ | ✓ | x | x | x | x | Option | x | x |

| SNMP | x | x | x | ✓ | ✓ | x | x | x | x | ✓ | ✓ | x |

| Power Measurement | ||||||||||||

| kW | ✓ | ✓ | ✓ | ✓ | ✓ | x | x | ✓ | ✓ | ✓ | ✓ | ✓ |

| kVA | ✓ | ✓ | ✓ | ✓ | ✓ | x | x | ✓ | ✓ | ✓ | ✓ | ✓ |

| kVAr | ✓ | ✓ | ✓ | ✓ | ✓ | x | x | ✓ | ✓ | ✓ | ✓ | ✓ |

| pf | ✓ | ✓ | ✓ | ✓ | ✓ | x | x | ✓ | ✓ | ✓ | ✓ | ✓ |

| kWh | x | ✓ | ✓ | ✓ | ✓ | x | x | ✓ | ✓ | ✓ | ✓ | ✓ |

| kVAh | x | ✓ | ✓ | ✓ | ✓ | x | x | ✓ | ✓ | ✓ | ✓ | ✓ |

| kVArh | x | ✓ | ✓ | ✓ | ✓ | x | x | ✓ | ✓ | ✓ | ✓ | ✓ |

| Event Recording And Plc Function | ||||||||||||

| Real Time Clock | ✓ | ✓ | ✓ | ✓ | ✓ | x | x | ✓ | ✓ | ✓ | ✓ | ✓ |

| Event Log | 400 | 50 | 250 | 250 | 250 | 40*** | 40*** | 40*** | 40*** | 350 | 350 | 300 |

| Plc Capability | x | x | ✓ | ✓ | ✓ | x | x | x | ✓ | ✓ | ✓ | ✓ |

* 2 are used if in Auto Mains Failure configuration

** Consumes 1 Analogue input

*** Has 40 event slots each of which can record up to 40 instances of an event